Equipment investments @Flexicel and Martinello

Flexicel aims to outdo itself

The Flexicel team is focused on improving their customer service. Besides manufacturing a product as perfect as possible according to customer requirements, they also develop new solutions for their customers. In this process they make use of the best testing technologies to be able to establish reliable technical data.

To be best in class, they have recently added the following test equipment to the various technologies already in place:

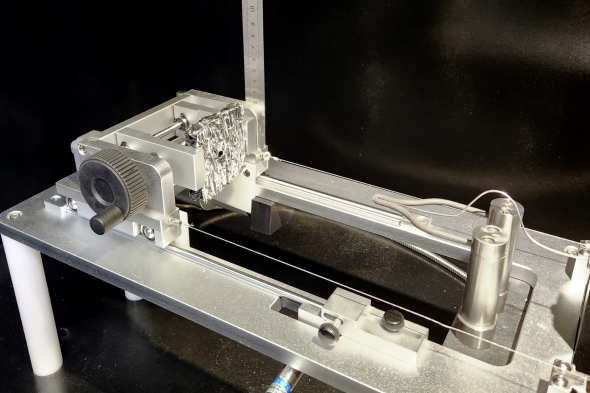

Acoustic absorption test device:

This technology allows to do precise measurements of the acoustic absorption and reflection levels of different materials at the different acoustic frequencies they could be exposed to. In other words, with this equipment, they can define the best solutions for insulation requirements in specific frequency ranges. They are also able to test and compare the absorption level of the various materials offered by Flexicel versus those of the competitor.

Glow wire test:

Using this test and following the standards EN60695-2, IEC60695-2 and VDE0471-2, Flexicel can determine the Glow Wire Flammability Index (GWFI). This test demonstrates the performance of their material rules at the beginning of the project, before doing the certifying official tests. That allows them to investigate different potential insulation solutions for environments where fire resistance is mandatory.

Martinello installs efficient suction and filtration system

End of 2023, Martinello installed a new suction and filtration system in the conversion area doubling the suction power from 25.000 m3/h to 50.000 m3/h. The main purpose of this new equipment is to reduce the powder dispersion in the conversion area.

The newly installed system allows the stocking of powders into big bags and facilitates the cleaning process of the products after the conversion process, reducing emissions in this part of the production process. The system includes a heat recuperator that retains the thermic energy of the aspirated air and releases it to the clean air back into the conversion area. To maximize the heat recuperation, all surfaces of the system have been insulated. The system is interconnected to the company Manufacturing Execution System which enables to access and download the performance data. Due to these features, the system has been qualified as a high technology investment benefitting from tax credit in accordance with the Italian legislation. This investment is the first step to refurbish and optimize the conversion area, a project to be continued in 2024.